Understanding Cable Railing Fittings

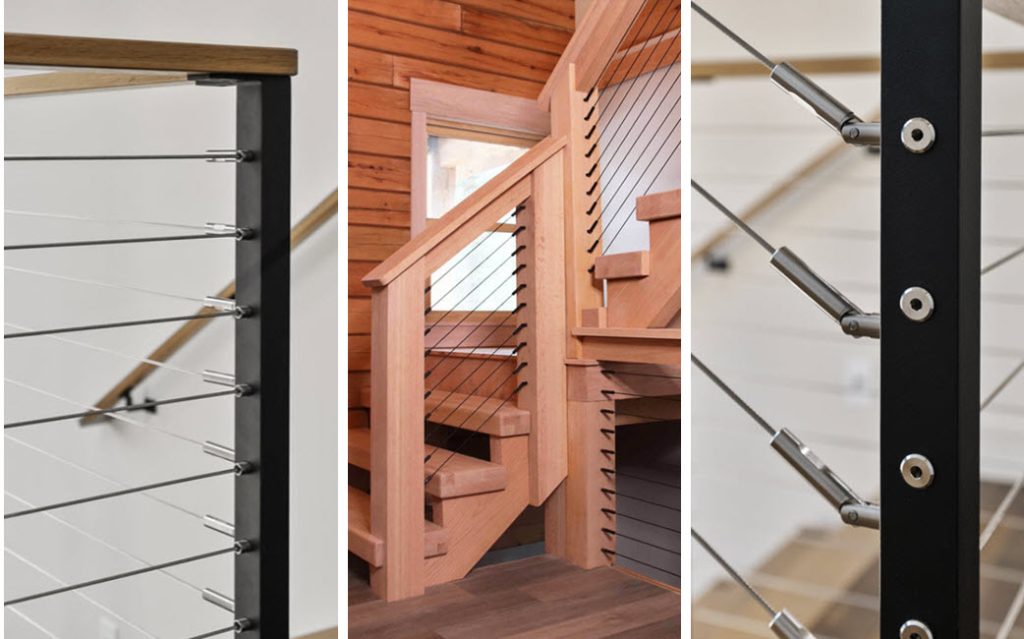

Cable railing systems have become increasingly popular for their sleek design and unobstructed views. However, navigating the various fittings and components available and learning how to install these systems can be overwhelming. Many of these systems require a swaging process. This process requires a special swaging tool to crimp the fitting on the end of the cable and an additional style fitting often referred to as a tensioner for the opposite cable end.

Our Swageless Railing System

To simplify the installation process, we offer a swageless cable railing fitting that is adjustable at both ends and allows for the same fitting to be used at each end of the cable. This innovative design eliminates the need for special tools or complicated assembly and can be installed with your hands, making it easy for both DIY enthusiasts and professionals.

Key Advantages of Our Swageless System

Adjustability: With the ability to adjust tension at both ends, you can achieve the perfect fit without hassle.

Can be disassembled – you can easily take apart the components anytime to adjust the cable or replace parts.

Minimalist Design: The sleek and simple aesthetic complements any architecture, enhancing the overall look of your railing.

Ease of Installation: We designed our fitting for straightforward installation, saving you time and effort.

Disadvantage of the Swageless System

Cable Type – It is currently available for use only on 316 stainless steel 1 x 19 -1/8th in cable.

Small Parts – Some of the components parts are small so be careful not to drop them.

Environment – The swageless cable fitting isn’t suitable for salt air environments.

Conclusion

Choosing the right cable railing fittings is crucial for the safety and aesthetics of your project. Our innovative swageless design reduces the number of parts to a minimum, making the selection and installation process smooth and efficient.

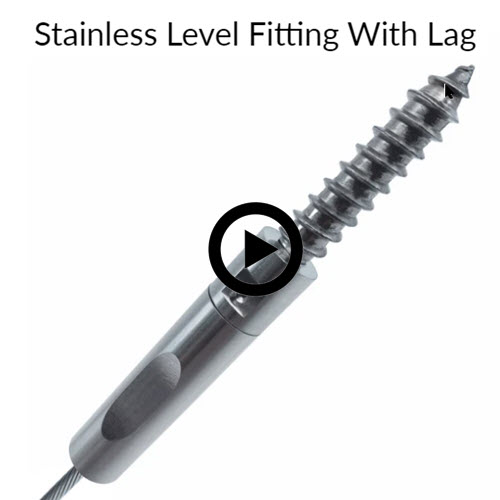

Check out these Videos on our YouTube channel to see the Swageless Fitting